//////////////////////////////////////////////////////////////////////

//

// File: Frequency-counter-4MHz-7seg-TMR1.c

//

// Author: rohith t

//

// Description:

//

// Measure frequency using TMR1 up to about 50MHz (depends on PIC chip input).

//

// Displays result on 8 x 7segment display.

//

// Compiler : mikroC, mikroElektronika C compiler

// for Microchip PIC microcontrollers

// Version: 5.0.0.3

//

// Note Testing:

//

// Tested on 16F877A

//

// Note measurement accuracy:

//

// The basic accuracy of the unit is set by the crystal oscillator accuracy.

//

// Requirements:

//

// Xtal clock : 4MHz

// (Use any type but better (smaller) ppm specification = better accuracy).

// (for different xtal frequency - recode frequency measurement part & tune).

//

// Target : 16F877A

//

// Accuracy: uses ONLY the main crystal clock as a reference

// - so the counter accuracy depends on the crystal.

//

// Note : re-tune gate_loop when ever code is added/removed.

//

// Check: By using simulator timer see code in gate.c (gate_loop)

// and here.

//

// Version:

// 1.01 16/Feb/06 - Change compiler to 5.0.0.3

// Changed to using RE0 and RE1 as 4017 controls.

// (Frees up analogue ports for other projects was A0,1).

// - more efficient so need to re-code time critical parts.

// 1.00 - Initial release.

//

//

//////////////////////////////////////////////////////////////////////

#include "bit.h"

#include "delay.h"

#include "gate.h"

#include "bcd.h"

#include "sevensegment.h"

//#include "usart_support.h"

//////////////////////////////////////////////////////////////////////

// Globals

//////////////////////////////////////////////////////////////////////

// globals for time critical code - to force compiler to keep.

volatile unsigned short sdmy=0; // for code critical section sdmy must not be optimised out

volatile unsigned int udmy=0; // for code critical section sdmy must not be optimised out

volatile unsigned int st_TMR1O; // updated in gate.c

// controls on this code comment out the following to stop using LCD

//#define USE_MY_LCD

//#define USE_LCD

//#define USE_USART

// This macro saves typing a lot of code.

#define REFRESH_7SEG display_str_8seg7(&op[2],dpIdx)

////////////////////////////////////////////////////////////////////////

void init_ports(void) {

ADCON1 = 0x06; // all digital outputs

PORTA = 0;

TRISA = 0xFF; // inputs

PORTB = 0;

TRISB = 0; // out

PORTC = 0x01; // b0 = 1 for 7seg

TRISC = 0x81; // B7 = i/p for USART, RC0 T1CKI-Timer1 i/p.

PORTD = 0;

TRISD = 0; // out

PORTE = 0;

TRISE = 0; // out

}

////////////////////////////////////////////////////////////////////////

// Start here

//

void main() org 440 {

char op[12] ; // Display string for seven segment display

unsigned short dpIdx=20 ; // Decimal point index into seven segment.

unsigned int i ; // loop counter

unsigned short st_TMR1L ; // Store Timer 1 low byte (after calced).

unsigned short st_TMR1H ; // store Timer 1 high byte time.

unsigned short refresh ; // refresh display interval count (during calcs).

unsigned long df = 0 ; // dispFlay frequency value to use.

unsigned short blinkc=0 ; // blink counter

#ifdef USE_LCD

char lcdop[4];

#endif

#ifdef USE_MY_LCD

char lcdop[4];

#endif

init_ports();

init_str_8seg7();

#ifdef USE_USART

USART_Init(2400);

#endif // USE_USART

// Timer 1

// prescale = 0, oscillator off, timer on, external clock, unsynchronized.

T1CON = (1<<TMR1ON) | (1<<TMR1CS) | (1<<T1SYNC);

// Enable Timer 1 interrupt flag so that the flag is updated

// interrupt not used just its output.

PIE1 = (1<<TMR1IE) ; // TMR1 overflow flag is enabled and can be polled.

// Note: actual interrupts not enabled.

#ifdef USE_MY_LCD

_LCD_init();

_LCD_Cmd(LCD_CLEAR);

_LCD_Cmd(LCD_CURSOR_OFF);

#endif

#ifdef USE_LCD

LCD_Config(&PORTB,2,1,0,7,6,5,4); // RS,E,W,D7..4

LCD_Cmd(LCD_CLEAR);

LCD_Cmd(LCD_CURSOR_OFF);

#endif

for(;;) {

// blink the led on port C.

if (blinkc>0) { // processor alive indicator

setBit(PORTC,2);

} else {

resBit(PORTC,2);

}

blinkc=~blinkc;

////////////////////////////

// Calculate frequency from timer 1

//

if (!(st_TMR1L==0 && st_TMR1H==0 && st_TMR1O==0) ) {

// Fails in 5.0.0.3

// df =( ((unsigned long) st_TMR1L) ) + \

// ( ((unsigned long) st_TMR1H)<<8 ) + \

// ( ((unsigned long) st_TMR1O)<16);

df = (unsigned long) st_TMR1L + (unsigned long) st_TMR1H * 256 + 65536 * (unsigned long) st_TMR1O;

} else {

df = 0;

}

REFRESH_7SEG;

// convert long to the display string.

ulong2bcd_p1(df); // conversion 1st part.

REFRESH_7SEG;

for (i=0;i<7;i++) {

ulong2bcd_process(void); // conversion 2nd part.

REFRESH_7SEG;

}

process_ulong2str(op);

REFRESH_7SEG;

// Initialize ready for next gate time

st_TMR1L = 0;

st_TMR1H = 0;

st_TMR1O = 0;

//////////////////////////

// GATE and REFRESH

//

// TUNE THIS GATE TIME to 1 second.

//

// 1. Tune the gate_loop first in gate.c

// 2. Then tune here (the overall gate time).

//

// 1.Break on

// gate_loop(1000,op);

// 2. reset the stop watch

// 3. step through until landing on statement:

// TMR1L_st = TMR1L;

//

// Check simluation stopwatch result is 1 second.

//

TMR1H = 0; // clear timer1 high count - the timer1 hardware.

TMR1L = 0; // clear timer1 low count - the timer1 hardware.

PIR1 &= ~(1<<TMR1IF); ; // clear Timer1 overflow bit.

//////////////////////////

// Start of gate time

//

gate_loop(1000,op); // op is the seven segment display string

delay_500_us();

delay_100_us();

delay_100_us();

delay_10_us();

delay_10_us();

delay_10_us();

asm {

CLRW

CLRW

CLRW

CLRW

CLRW

}

st_TMR1L = TMR1L; // get counter values before it updates

st_TMR1H = TMR1H;

/// End of gate time

////////////////////

// test for overflow after tune delay

if ( PIR1 & (1<<TMR1IF) ) {

PIR1 &= ~(1<<TMR1IF); // clear the bit.

st_TMR1O += 1; // increase high count.

}

#ifdef USE_MY_LCD

// lots of refresh needed to keep approx 1ms 7seg refresh rate

_LCD_Print(2,1,"FREQ:"); REFRESH_7SEG;

_LCD_Print(2,6,op); REFRESH_7SEG;

_LCD_Print(1,1,"H"); REFRESH_7SEG;

ByteToStr(st_TMR1H,lcdop); REFRESH_7SEG;

_LCD_Print(1,2, lcdop); REFRESH_7SEG;

_LCD_Print(1,9,"L"); REFRESH_7SEG;

ByteToStr(st_TMR1L,lcdop); REFRESH_7SEG;

_LCD_Print(1, 10, lcdop); REFRESH_7SEG;

#endif

#ifdef USE_LCD

// lots of refresh needed to keep approx 1ms 7seg refresh rate

LCD_Out(2,1,"FREQ:"); REFRESH_7SEG;

LCD_Out(2,6,op); REFRESH_7SEG;

LCD_Out(1,1,"H"); REFRESH_7SEG;

ByteToStr(st_TMR1H,lcdop); REFRESH_7SEG;

LCD_Out(1,2, lcdop); REFRESH_7SEG;

LCD_Out(1,9,"L"); REFRESH_7SEG;

ByteToStr(st_TMR1L,lcdop); REFRESH_7SEG;

LCD_Out(1, 10, lcdop); REFRESH_7SEG;

#endif

#ifdef USE_USART

// test shift left in 5.0.0.3

// st_TMR1O=5;

// st_TMR1H=20;

// df = 70 + 21 * 256 + 65536 * st_TMR1O; // OK

// df = 70 + 21 * 256 + st_TMR1O<<16; // fails

// USART_Print("LONG:");

// LongToStr(df,bcd_ascii); // check that df is accurate

// USART_Println(bcd_ascii);

USART_Print("FREQ:");

USART_Println(op);

USART_Print("H:");

ByteToStr(st_TMR1H,op);

USART_Print(op);

USART_Print(" L:");

ByteToStr(st_TMR1L,op);

USART_Print(op);

USART_Print(" O:");

WordToStr(st_TMR1O,op);

USART_Println(op);

#endif // USE_USART

}

}

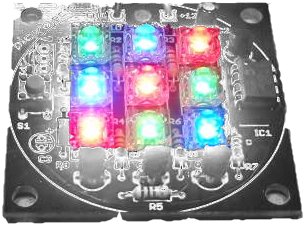

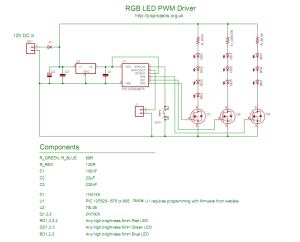

This project is an update to the original RGB LED PWM Driver. The new version allows the use of either 5mm LEDs or the square bodied Superflux / Piranah style LEDs. The circuit now uses bipolar transistors rather than MOSFETs which make it more suitable for novice constructors and for the first time this project is available as a kit with all parts required to assemble the PCB including the superflux LEDs.(power supply not included)

This project is an update to the original RGB LED PWM Driver. The new version allows the use of either 5mm LEDs or the square bodied Superflux / Piranah style LEDs. The circuit now uses bipolar transistors rather than MOSFETs which make it more suitable for novice constructors and for the first time this project is available as a kit with all parts required to assemble the PCB including the superflux LEDs.(power supply not included)

.jpg)